How smart energy management reduces energy consumption

With the help of smart energy management, the Kitzsteinhorn optimizes its operational processes and reduces its carbon footprint.

Numbers are his passion. And that’s a good thing, for as energy manager, Stefan Reisinger has to juggle extensive numerical data and monitor parameters for optimizing energy consumption daily.

Despite a record fiscal year and consequently more visitors, we were able to reduce our energy consumption by 2.6%!

Goal: Reducing consumption

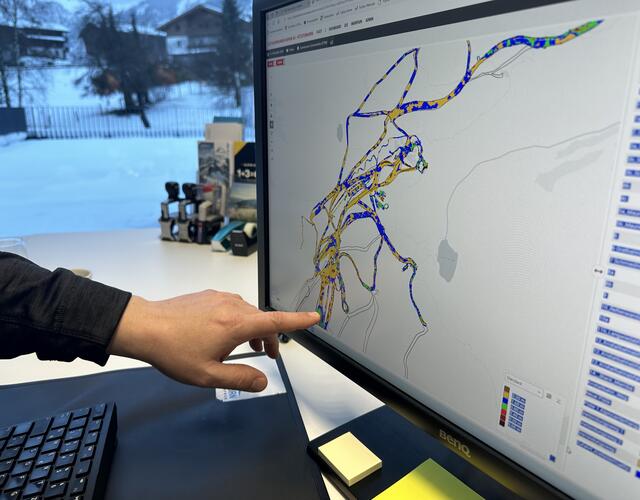

In 2015, the Gletscherbahnen Kaprun AG was Austria’s first cableway company to be certified according to ISO 50001 (international standard for energy management systems), meaning that it collects, analyzes and optimizes all of the energy it consumes. Stefan Reisinger has been involved in systematically developing the company’s energy management system from the very beginning and reports: “Energy monitoring requires that all company figures are available in order to achieve highest possible energy efficiency. That turns out to be quite challenging when over 100 measuring points both on the mountain and in the valley are involved. So, our first step was to feed all figures in one dashboard and visualize the whole mountain. That allows me to constantly monitor consumption in the charts and intervene to take optimizing actions, if necessary. Our goal is clear: Reducing consumption!”

The small city of Kitzsteinhorn

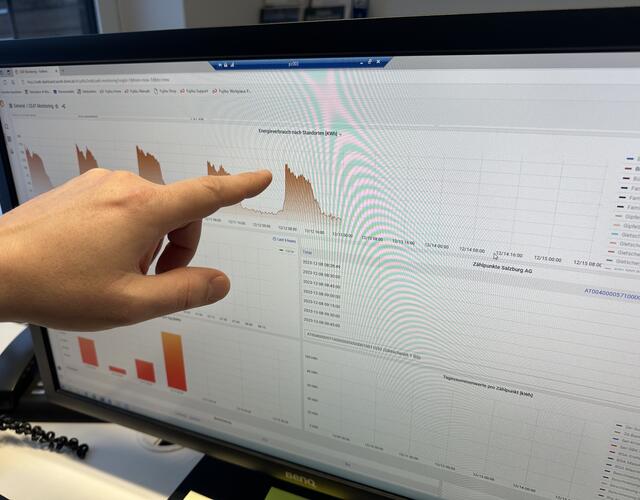

On peak days, the Kitzsteinhorn counts 12,000 visitors and is therefore to be treated like a small city in need of considerable energy. Stefan Reisinger knows: “Besides cableway operation, snowmaking and office buildings, there are also numerous workshops that have to be powered. Being at an elevation of over 2,000 meters, the Kitzsteinhorn features an own electrical, metalwork and plumbing department. Six company-owned restaurants switch on their lights and appliances in the morning to welcome thirsty and hungry skiers and snowboarders throughout the day. That’s when I see particularly strong current peaks in my chart.” It’s these current peaks Stefan Reisinger focuses on, determines what exactly causes them and adopts measures for cutting down energy consumption as much as possible during these heights. He gives an example: “We can counteract the peaks by not switching on the heavy equipment in the kitchen while ski lifts start operating. Staggered activation of the devices helps enormously. Even just slightly reducing lift speed makes a considerable difference in energy consumption. With the 3K K-onnection, for instance, reducing the number of gondolas and speed on bad weather days saves a significant amount of energy, and visitors won’t even notice.”

Positive figures in energy balance

To Stefan Reisinger, energy management is like juggling ten balls at once: “I’m constantly monitoring, where figures deviate and where I can make adjustments. My monitor shows me all figures from slope grooming to self-generated energy. By adding a third turbine to our hydropower plant Grubbach and further expanding our PV installations, we could increase our self-generated power by 42.4%.” The GPS-based slope management system SNOWsat allows super-efficient grooming with its snow depth measurement system: “That saves up to 4% of fuel.”

Energy reduction of 2.6%

The energy manager’s job is especially satisfying when juggling figures results in great success for the company. In 2023, both Stefan Reisinger and the Gletscherbahnen Kaprun can be happy about an energy reduction of 2.6%. Stefan is thrilled: “An external auditor conducts the examination for the ISO certification. It feels good to be rewarded with a negative figure eventually – despite a record fiscal year, we were able to reduce our energy consumption. So, we’re definitely on the right track and with the help of monitoring, we’re already setting new goals to save even more energy in the future.”